The 1 1/2inch 1500LBglobe valve,made of A105N are best suited for throttling application at high pressure and temperature.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A105NMethod of Operation:

HandwheelQuick Detail

|

Type |

Globe Valve |

|

Nominal Diameter |

1 1/2 Inch |

|

Nominal Pressure |

1500LB |

|

Construction |

Pressure Seal Bonnet |

|

Connection |

SW |

|

Design & Manufacture |

B16.34 |

|

SW Dimension |

ASME B16.11 |

|

Test & Inspection |

API598 |

|

Body Material |

A105N |

|

Disc Material |

304+STL |

|

Temp. Range |

-29~38°C |

|

Media |

Oil, Gas |

Features

·Proven pressure seal design.

·Body guided disc eliminates side thrust and provides longer disc, seat and body life.

·Body made of superior strength forgings and optional cast steel.

·Optional live-loading of packing.

·Other sizes and pressure classes available.

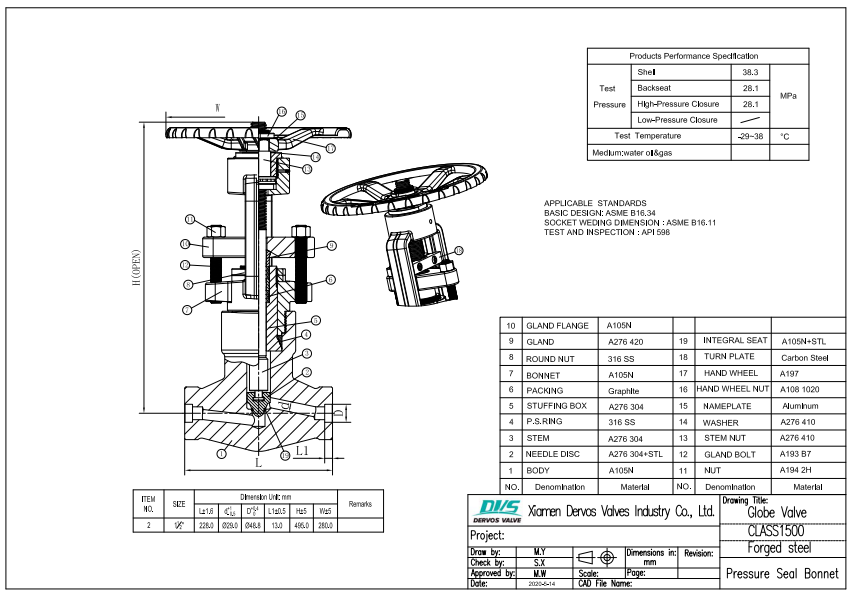

Technical Drawing

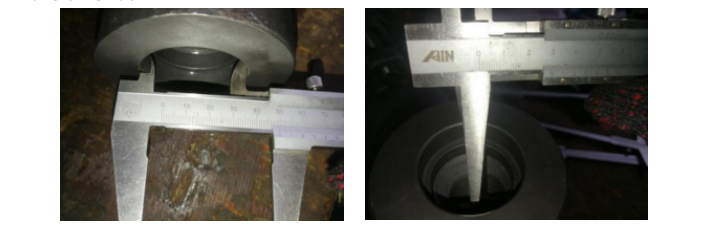

Dimension Check

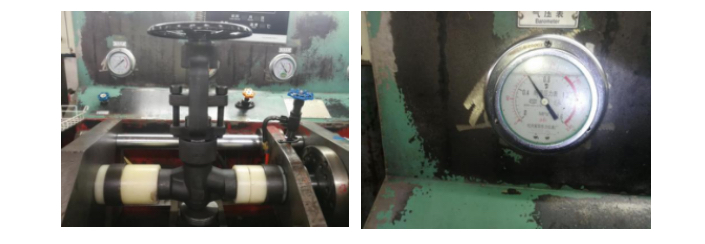

Witness Tests

Our Service

A good customer service is as valuable as product itself. In Dervos, we will offer a full range of customer service to make you feel easy when doing business with us.

Providing weekly production report

When production begins, you will get production report weekly, so that you can have good command of product status and report to your customer at the meantime.

Offering warranty of 18 months

18 months warranty period will be offered after shipment, no concern to purchase valve from Dervos.

Providing solutions within 3-days for complaints

All the complaints will be solved within 3 days, in this case, you can timely reply and solve problems for your customer, to relax them even when complaints happening.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.