The 1 1/2inch 1500LB globe valve,made of one kind of alloy steel F22, is the best answer to working conditions under high pressure and temperature .

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

F22Method of Operation:

HandwheelQuick Detail

|

Type |

Globe Valve |

|

Size |

1 1/2 Inch |

|

Pressure |

1500LB |

|

Construction |

Pressure Sealed;OSY |

|

Connection Type |

Socket Weld |

|

Operation Type |

Handwheel Operated |

|

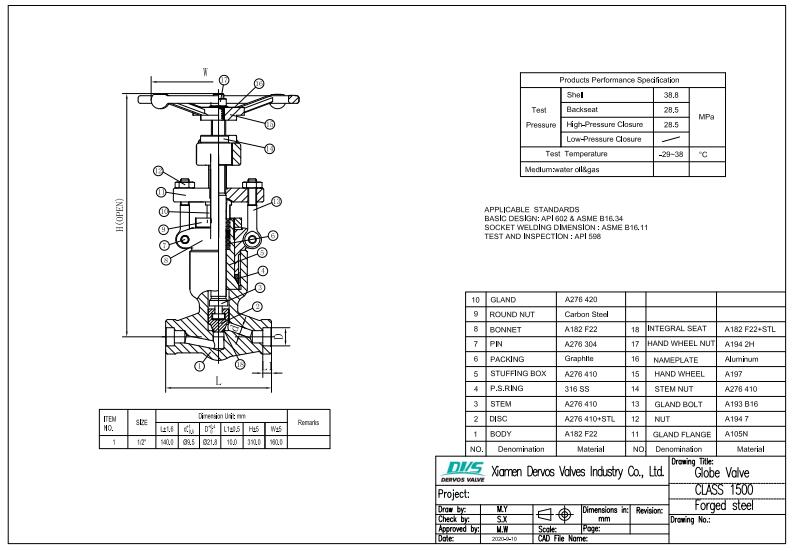

Design Code |

API602 & ASME B16.34 |

|

Socket Weld Dimension |

ASME B16.11 |

|

Test & Inspection |

API 598 |

|

Body Material |

F22 |

|

Trim Material |

SS304+STL |

|

Temperature Range |

-29~38℃ |

|

Application |

Water, Oil, Gas |

|

Origin |

China |

Features

1. Flexible wedge gate, full guide;

2. Compact structure, reliable sealing, excellent performance and nice appearance;

3. Only one sealing surface on the valve body and disc brings convenient maintenance;

4. Packing can be replaced in-site;

Technical Drawing

Dimension Check

Nameplate&Packaging

About Dervos

Xiamen Dervos Valves Industry Co.,Ltd (stock code 861601), founded in June 2008, is a one-stop industrial valves supplier integrated of R&D, manufacture, resource integration, and trade service. For 12 years, Dervos has been committed to finding solutions for industrial needs and providing professional service for both general and specialized valves.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.