Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

ASTM A216 WCB +13CrMethod of Operation:

Handwheel OperationThe 2 inch 1500LB globe valve, made of ASTM216 WCB, is designed as per BS 1873. It is operated by a handwheel and is connected with pipeline by RTJ. The body and the disc of the globe valve contain 13Cr, therefore this valve enjoys a better ability to resist corrosion.

Quick Detail

|

Type |

Globe Valve |

|

Nominal Diameter |

2 Inch |

|

NominalPressure |

1500LB |

|

Construction |

Bolted Bonnet |

|

Connection |

RTJ |

|

Operation |

Handwheel |

|

Design & Manufacture |

BS 1873 |

|

End to End |

ASME B16.10 |

|

Flange End Dimension |

ASME B16.5 |

|

Test & Inspection |

API 598 |

|

Temperature Range |

-29℃~+425℃ |

|

Body Material |

ASTM A216 WCB +13Cr |

|

Disc Material |

ASTM A105 WCB +13Cr |

|

Media |

W.O.G. |

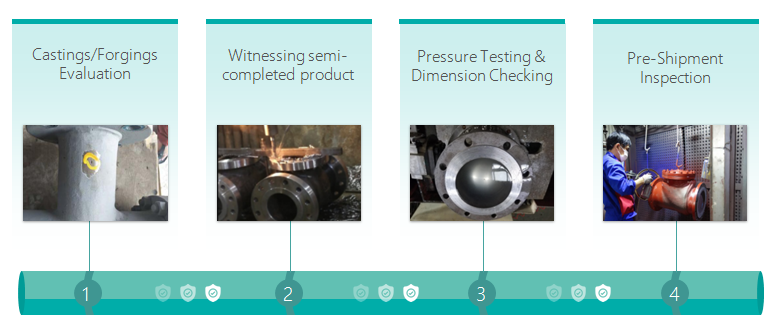

Dervos Quality Checking System

In Dervos, we control quality throughout the whole manufacturing process.

Casting inspection:

We can find out the problem of raw material, such as shoddy casting, unqualified wall thickness, chemical composition and so on, which ensure that you will not be cheated.

Machining Inspection:

On the one hand, we could ensure machining accuracy through this process. On the other hand, we could find out machining mistake as early as possible, to win more time for repairing and remaking

Final Inspection:

Final inspection activities include document and QC record review, visual examination, dimension check, pressure test, painting and packing check. You don’t need to come and inspect in person and all the documents could be provided as proof.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.