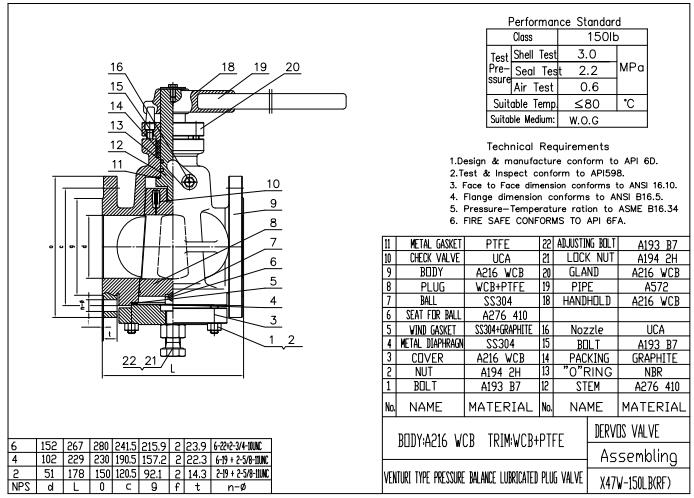

The inverted pressure balanced lubricated plug valve is 2inch and 150 LB. Manufactured as per API6D, the valve is capable in manifolds and production services of oil fields, asphalt plants, others.

Product Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

WCBMethod of Operation:

LeverQuick Details

|

Type |

PlugValve |

|

Size |

2 Inch |

|

Pressure |

150LB |

|

Construction |

Inverted Type, Lubricated Type, Pressure Balanced |

|

Connection |

Flange End |

|

Operation |

Lever, Wrench |

|

Body Material |

A216 WCB |

|

Design Code |

API6D |

|

Face to Face Code |

ANSI B16.10 |

|

Pressure & Temp Code |

ANSI B16.34 |

|

Test & Inspection Code |

API 598 |

|

Temperature Range |

<80℃ |

|

Medium |

Water, Oil and Gas |

The pressure balanced lubricated plug valves boast compact construction and can be easily maintained in line.. These valves are suitable for mediums that are used in various industries such as petroleum, chemical industry, pharmacy, chemical fertilizer, electric power industry, etc.

Features

· Developed to be used in Manifolds and Production services of Oil Fields, Asphalt Plants, others.

· Hard coated Plug and erosion resistant design.

· Internal sealant path to improve the sealant on the seats.

· Highly used in pipelines systems where the main fluids are: Gas, Oil and Petroleum.

· Valve Position indicator is equipped.

· Fire safe conforms to API 6FA.

Technical Drawing

About Dervos

Dervos valves can be widely used in varieties of industries, such as petrochemical, pipeline, oil & gas, marine, water treatment, power station industries and etc.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.