A diaphragm valve is a type of valve widely used in industrial applications. It controls the fluid by isolating the fluid from the internal moving parts of the valve body through a flexible diaphragm. Due to its unique design, diaphragm valves offer distinct advantages in many application scenarios.

Structural characteristics

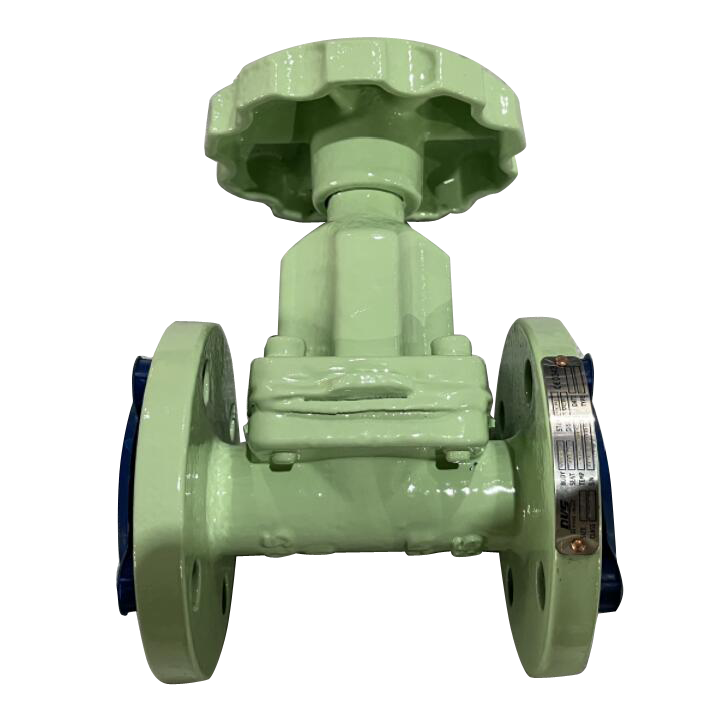

The main components of a diaphragm valve include the valve body, diaphragm, bonnet, stem, and handwheel. The interior of the valve body is designed with a smooth passage to allow fluid to flow through easily. The diaphragm is typically made of elastic materials such as rubber or fluoroplastic and is fixed between the valve body and the bonnet, serving as both a seal and a barrier. The stem is connected to the diaphragm via threads or other mechanical devices, and the handwheel is used to drive the stem up and down.

Working principle

The working principle of a diaphragm valve is relatively simple. By rotating the handwheel or operating the actuator, the stem moves the diaphragm up and down. When the diaphragm moves down and presses against the valve seat, the valve closes, blocking the fluid. When the diaphragm moves up and away from the valve seat, the valve opens, allowing the fluid to pass through.

Types

1. Based on the driving method, diaphragm valves can be divided into manual diaphragm valves, pneumatic diaphragm valves, and electric diaphragm valves.

2. Based on the structural form, diaphragm valves can be divided into straight-through and angle type.

3. Based on diaphragm materials, diaphragm valves can be divided into rubber diaphragm valves and fluoroplastic diaphragm valves.

Advantages

1. Leak-Free Design: Diaphragm valves offer excellent sealing performance, effectively preventing fluid leakage.

2. Corrosion Resistance: With the appropriate diaphragm material, diaphragm valves can be used with various corrosive media.

3. Easy Maintenance: Simple structure, easy to disassemble and replace the diaphragm, resulting in low maintenance costs.

4. Low Fluid Resistance: Smooth flow path design results in low fluid resistance, making them suitable for high-viscosity fluids and fluids containing particulates.

Application Areas: Diaphragm valves are widely used in industries such as chemical, pharmaceutical, food and beverage, water treatment, and electronics.

Previous :

Introduction to Y-Type Globe ValveNext :

What is a Threaded Bonnet Gate Valve?