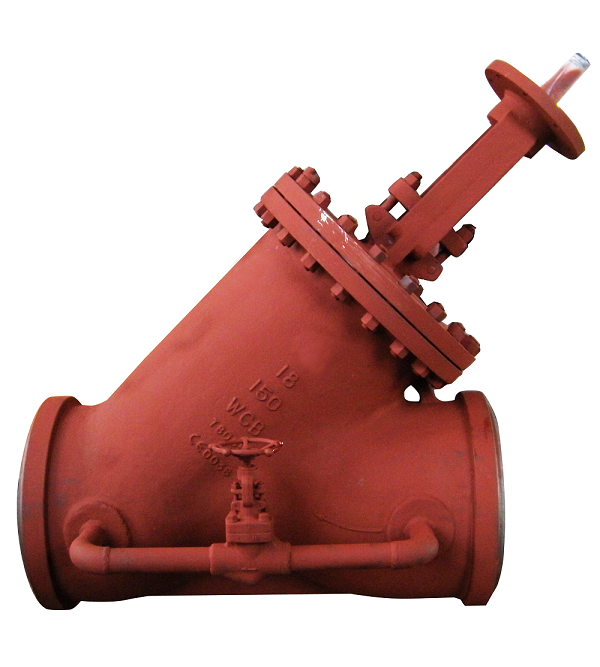

The Y-type globe valve is a common type of valve widely used in various industrial fields such as petroleum, chemical, power, and water treatment. Its unique design makes it excellent for regulating and shutting off fluid flow, offering high reliability and durability.

Structure and Principle

The Y-type globe valve consists of main components such as the valve body, bonnet, stem, disc, and handwheel. Its name is derived from the Y-shaped structure of its valve body chamber. This design not only reduces the resistance of fluid passing through but also facilitates the movement of the disc. The stem is driven by a handwheel or an electric actuator. When the stem rises, the disc moves away from the seat, allowing fluid to pass through. When the stem lowers, the disc contacts the seat, cutting off the fluid flow.

Features and advantages

1. Low Fluid Resistance: Due to the Y-type structural design, the resistance encountered by the fluid passing through is lower than that of a standard globe valve, resulting in minimal flow loss.

2. Excellent Sealing Performance: The sealing surfaces of the disc and seat are made of hard alloys or other wear-resistant materials, ensuring reliable sealing and long service life.

3. Easy Operation: The handwheel operation is simple, and the valve can be equipped with electric or pneumatic actuators for remote control and automation.

4. Easy Maintenance: The valve body has a simple structure, making it easy to disassemble and maintain, thus reducing maintenance costs.

Application area

1. Petroleum and Natural Gas Industry: Used in oil pipelines and natural gas transmission systems, featuring high-pressure resistance and corrosion resistance.

2. Chemical Industry: Suitable for pipeline systems with various corrosive media, possessing excellent anti-corrosion performance.

3. Power Industry: Used in steam and cooling water systems, resistant to high temperature and high pressure.

4. Water Treatment: Utilized in wastewater treatment plants and waterworks for cutting off and regulating water flow.

Installation and maintenance

1. Location Selection: Choose the appropriate location based on the pipeline direction to ensure convenient valve operation.

2. Installation Direction: Install according to the medium flow direction markings to avoid improper sealing caused by reverse installation.

3. Regular Inspection: Regularly check the valve's sealing performance and operational flexibility, and replace damaged seals promptly.

4. Lubrication Maintenance: Regularly lubricate the threaded parts of the valve stem to maintain smooth operation.

Previous :

What is a Wafer Ball Valve?Next :

What is A Diaphragm Valve?