The ball of floating ball valve is floating. Under the action of medium pressure, the ball can produce certain displacement and press tightly on the sealing surface at the outlet end to ensure the sealing at the outlet end.

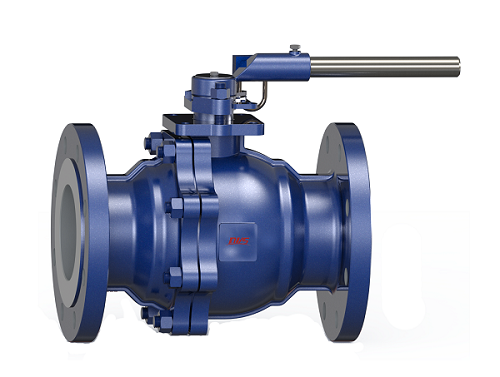

Structure

1. The valve stem should be inverted, anti-blowout structure. The valve stem of the valve should not be limited by the packing gland fasteners. To be precise, the valve stem will not be separated from the valve due to the loosening of the valve stem sealing fasteners when the valve is under pressure.

2. Anti-static structure. It consists of a stainless steel ball and a spring. One group is placed in the hole at the end of the valve stem, keeping in contact with the ball; the other group is placed on the cylinder of the valve stem, keeping in contact with the valve body, so that the possible static electricity is guided away from the valve body.

3. Fire-safe structural design. When the sealing seat is burned, the main and auxiliary valve bodies should be in contact with the sphere and maintain a certain degree of sealing. The connecting surfaces of the main and auxiliary valve bodies shall adopt gaskets with fire safety functions, such as metal wound gaskets. At the packing seal of the valve stem, when the packing (PTFE) is burned, there should be a graphite ring to prevent the medium from leaking out.

4. There should be a limit mechanism to accurately limit the ball to be in the "open" or "close" position.

5. There should be a platform for installing pneumatic, electric and worm gear actuator brackets on the valve body.

Sealing Principle

The opening and closing part of the floating ball valve is a sphere with a through hole equal to the diameter of the pipe in the middle. The inlet and outlet ends are each equipped with a sealing seat made of PTFE, and are contained in a metal valve body. When the through hole in the sphere coincides with the pipeline channel, the valve is in the open state; when the through hole in the sphere is perpendicular to the pipeline channel, the valve is in the closed state.

When the ball valve is in the closed position, the medium pressure at the inlet end acts on the ball, generating a force to push the ball, making the ball press the sealing seat at the outlet end tightly, and a contact stress is generated on the tapered surface of the sealing seat to form a contact zone. The force per unit area of the contact zone is called the working specific pressure of the valve seal. When this specific pressure is greater than the necessary specific pressure for sealing, the valve is effectively sealed. This kind of sealing method that does not rely on external force is sealed by medium pressure, which is called medium self-sealing.