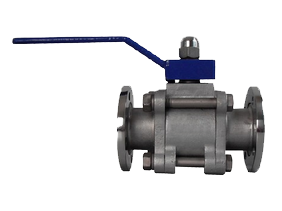

Vacuum ball valve refers to a ball valve whose working pressure is lower than the standard atmospheric pressure and forms a certain vacuum. Its working principle is similar to that of a vacuum butterfly valve, and the valve is opened and closed by rotating the ball fixed on the rotating shaft by 90°. Because the valve body and stem are made of stainless steel in its structure, and the sealing materials such as the valve seat and packing are all polytetrafluoroethylene, it is suitable for working conditions where the medium is air, water, steam, acid, alkali, etc.

Features

1. It adopts 1/4 rotary pneumatic or electric actuator, which works smoothly, and the valve switch has electric signal output, which can be used both by hand and by electricity;

2. It not only has simple structure and good sealing performance, but also has small installation size, small driving torque, simple operation, and easy to realize rapid opening and closing;

3. It can be used in a high vacuum state or a low pressure system to achieve the advantages of both positive and negative pressure.

Connection Forms

(1) Flange connection: This is the most commonly used connection form in valves. According to the shape of the joint surface, it can be divided into the following types:

① Smooth type: used for valves with low pressure, it is more convenient to process;

② Concave-convex type: the working pressure is relatively high, and medium-hard gaskets can be used;

③ Tongue and groove type: gaskets with large plastic deformation can be used, which are widely used in corrosive media and have good sealing effect;

④ Trapezoidal groove type: use oval metal ring as gasket;

⑤ Lens type: The gasket is in the shape of a lens and made of metal;

⑥ O-ring type: It is a relatively new flange connection form developed with the emergence of various rubber O-rings, and its sealing effect is more reliable than ordinary flat washers.

(2) Threaded connection: This is a simple connection method, often used in small valves. It is divided into two situations:

① Direct sealing: The internal and external threads directly play a sealing role.

② Indirect sealing: The power of thread tightening is transmitted to the gasket between the two planes, so that the gasket acts as a seal.