The Heating Jacket Gate Valve plays a crucial role in industries such as oil, chemical, and pharmaceutical sectors. Its primary function is to maintain the temperature of the valve and its internal fluid by circulating a heating medium within the jacket, preventing the fluid from solidifying or freezing due to a drop in temperature.

Selecting the appropriate Heating Jacket Gate Valve is crucial for ensuring smooth process flow and extending the equipment's lifespan.

1. Understand the Process Requirements

(1) Working Temperature and Pressure

Determine the operating temperature and pressure range of the pipeline system to select a Heating Jacket Gate Valve suitable for these conditions. The valve's material and structure must be able to withstand these parameters.

(2) Medium Characteristics

Understand the physical and chemical properties of the medium, including its corrosiveness, viscosity, and whether it tends to crystallize or solidify. Choose valve materials and sealing materials that are compatible with the medium to prevent corrosion and leakage.

(3) Heating Medium

Determine the type of heating medium (such as steam, hot oil, or electrical heating) and select a jacket design and materials that are compatible with it. Different heating media have varying design requirements for the jacket, so choose the type that best suits the application.

2. Choose the Appropriate Valve Material

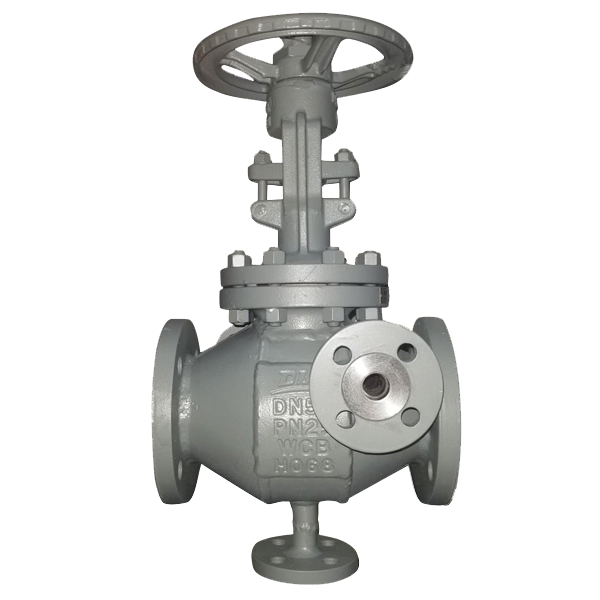

(1) Valve Body Material

Common valve body materials include cast steel, stainless steel, and alloy steel. When selecting, consider the corrosiveness of the medium and the operating temperature. For highly corrosive media, stainless steel or alloy steel is a better choice.

(2) Sealing Material

The choice of sealing material should consider the chemical properties of the medium and the operating temperature. Common sealing materials include PTFE and flexible graphite. Select the appropriate sealing material based on the specific operating conditions.

3. Pay Attention to Valve Size and Connection Method

(1) Valve Size

Select the appropriate valve size based on the pipeline diameter to ensure that the valve connects smoothly with the piping system and does not affect the flow during operation.

(2) Connection Method

Common connection methods for Heating Jacket Gate Valves include flanged connections and welded connections. Depending on the pipeline design, choose the appropriate connection method: flanged connections facilitate easy disassembly, while welded connections offer greater reliability.

4. Consider the Operation Mode of the Valve

(1) Manual Operation

For applications with lower operation frequencies or where automatic control is not required, a manually operated Heating Jacket Gate Valve is a cost-effective and practical choice.

(2) Automatic Operation

If remote control or automated operation is required, you can choose a Heating Jacket Gate Valve equipped with an electric or pneumatic actuator. This type of valve can be controlled through a control system to achieve automatic opening, closing, and adjustment, making it suitable for highly automated production environments.

5. Consider Cost and Maintenance

(1) Initial Investment

When selecting a Heating Jacket Gate Valve, it is important to consider not only the initial purchase cost but also the valve's longevity and reliability to reduce future replacement and maintenance costs.

(2) Maintenance Convenience

Choose a valve type with a simple structure and easy maintenance to reduce downtime and maintenance difficulty.