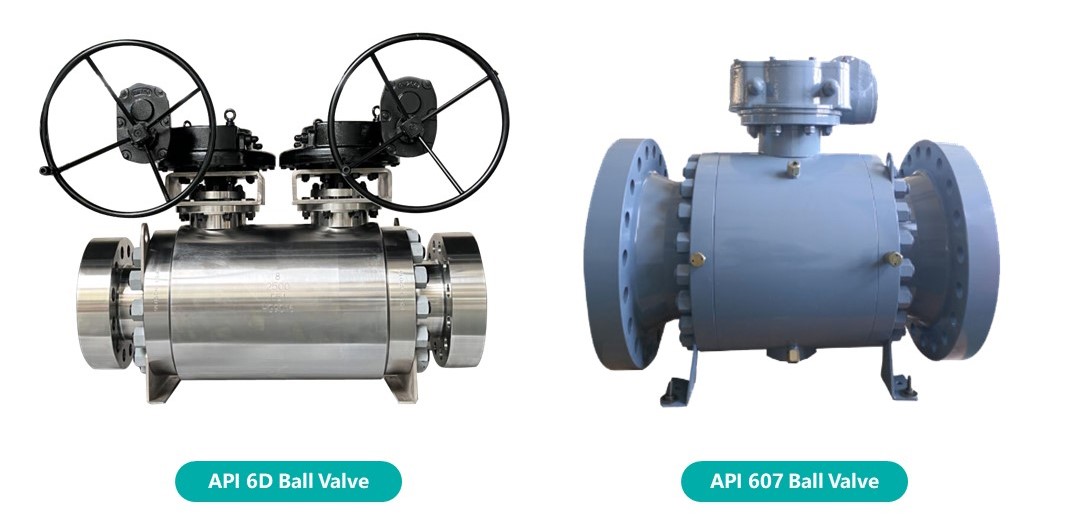

In the industrial valve sector, API 607 and API 6D are two commonly referenced and significant standards, each applicable to ball valves under different operating conditions. Understanding their differences helps engineers and procurement personnel select the right product for specific applications.

API 607 primarily applies to fire-safe valves, including ball valves, gate valves, and plug valves. Its objective is to ensure the sealing performance of valves during a fire to prevent the fire from spreading. API 607 ball valves are typically used in high-risk conditions such as chemical, petrochemical, and oil and gas industries.

API 6D, on the other hand, focuses on ball valves used in pipeline transportation systems, covering aspects such as design, manufacturing, testing, and operation. This standard is widely applied in long-distance pipelines, LNG stations, and other pipeline transportation scenarios, emphasizing valve reliability and operational performance. Depending on the specific application, fire-safe designs may or may not be required under API 6D.

API 607 ball valves must meet fire-safe design requirements, ensuring basic sealing functionality in high-temperature environments. Seats, seals, and other critical components are required to use fire-resistant materials to prevent media leakage even if damaged during a fire.

API 6D ball valves, in contrast, emphasize structural integrity and flow control performance. They typically feature double block and bleed (DBB) functionality and a full-bore design to minimize fluid resistance. Additionally, API 6D mandates reliability under high-pressure and low-temperature conditions, with fire-safe design being optional based on the specific application requirements.

API 607: Sealing performance is the most critical aspect of the API 607 standard. It requires valves to maintain a certain level of sealing capability during a fire to prevent media leakage. Fire-safe valve seals, seats, and other components must possess high-temperature resistance, typically utilizing metal seals or materials designed to withstand elevated temperatures. These valves must pass high-temperature exposure tests for a specific duration to ensure that they can endure temperature fluctuations and provide effective sealing in fire scenarios.

API 6D: While API 6D emphasizes valve sealing performance, it does not impose stringent fire-sealing requirements like API 607. The inclusion of fire-safe design in API 6D valves depends on the application. The standard focuses on sealing performance under normal operating conditions, including media leakage control (e.g., gas-tightness testing). API 6D sealing requirements are primarily centered on standard pressure and temperature conditions, making the valves suitable for most pipeline transportation media.

API 607: To ensure fire-safe functionality, API 607 imposes stringent requirements on material selection, particularly concerning the high-temperature resistance of seals and seats. Commonly used materials include metals such as stainless steel alloys and nickel alloys, as well as specialized fire-resistant polymer materials. These materials must retain their functionality under the high-temperature conditions of a fire.

API 6D: API 6D focuses more on corrosion resistance, wear resistance, and pressure tolerance. Depending on the type of pipeline medium (e.g., oil, gas, chemicals), the materials used for ball valves may include stainless steel, carbon steel, and aluminum bronze. The standard requires materials to exhibit strong structural stability, capable of withstanding the pressure, flow, and temperature variations encountered during pipeline transportation.

API 607: API 607 outlines stringent fire testing procedures. Valves must undergo tests simulating fire conditions, and their leakage rates must comply with specified requirements. These tests ensure the functionality and safety of valves in fire scenarios.

API 6D: API 6D encompasses a range of pressure tests, including shell pressure tests, low-pressure sealing tests, and high-pressure sealing tests. The focus of these tests is on the valve's airtightness and mechanical performance, ensuring stability under high-pressure transport conditions.

API 607: Fire resistance is a critical requirement under the API 607 standard. It ensures that valves remain operable in high-temperature environments, preventing fire-induced damage to equipment. As a result, API 607 ball valves typically exhibit greater durability compared to standard API 6D ball valves, especially during fire incidents.

API 6D: API 6D ball valves are designed with a focus on long-term operational stability and durability. They are engineered to withstand frequent open-close operations, particularly under sustained pressure and flow control. While fire resistance is not a primary focus, the standard emphasizes high-load durability and operational stability, making these valves well-suited for prolonged, intensive use in pipeline transport applications.

API 607: Due to fire-safe requirements, maintaining API 607 ball valves is relatively complex. Regular inspections of the sealing materials for aging are essential, especially when exposed to high-temperature environments during operation. During cleaning and maintenance, special attention must be given to potential damage to seals and valve seats to ensure that fire-resistant performance remains intact.

API 6D: Maintenance of API 6D ball valves depends on the specific application. For scenarios involving high flow rates or low-temperature operations, periodic checks of sealing and operational performance are crucial. Particular focus should be placed on wear and tear of O-rings and valve seats, as these are key areas for maintenance in API 6D ball valves.

Previous :

Overview of T StrainerNext :

DERVOS Hydrogen Valve Inspection Requirements