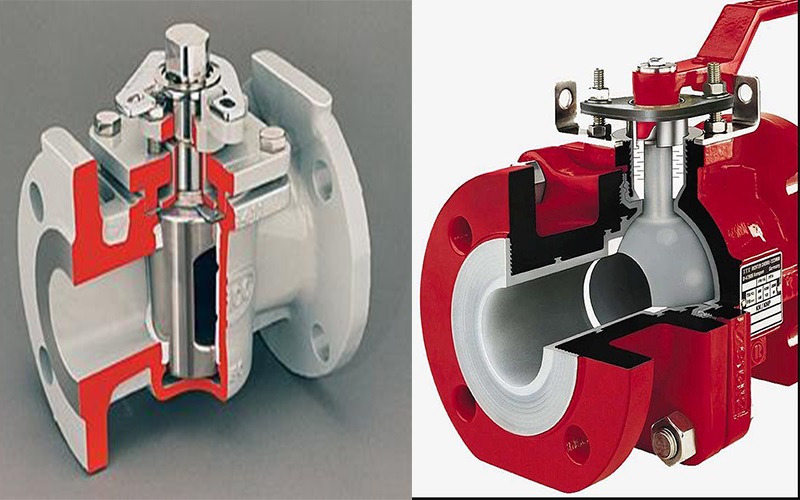

The plug valve is a relatively old type of valve, including sleeved plug valve,lubricated plug valve and multi way plug valve. It relies on the plug body to rotate around the center line of the valve body to achieve the purpose of opening and closing. The function of the plug valve is generally used to cut off, distribute and change the medium flow direction. The plug valve has a simple structure; the external dimensions are small; only 90% of the fluid resistance is required during operation. It is widely used, especially in low pressure, small diameter and medium temperature. The disadvantages of the plug valve are that the switch is laborious, the sealing surface is easy to wear, and it is easy to get stuck at high temperature and pressure, which is not suitable for regulating the flow.

The ball valve is evolved from a plug valve. Its opening and closing member is a ball. The ball is rotated 90 degrees around the axis of the valve stem to achieve the purpose of opening and closing. It is mainly used to cut, distribute and change the flow of the medium Orientation, the ball valve designed as a V-shaped opening also has a good flow adjustment function.

When used for shut-off, the plug valve has a slightly better adjustment capacity than the ball valve, but has limited advantages. Although the plug valve has a sealing surface much larger than the ball valve, the sealing effect is good, but it also brings the disadvantage of too much torque and insufficient flexibility. Due to the influence of the weight of the cock, the conventional positive cock structure is difficult to achieve a large caliber. If you want to use a large-size valve, you must use an inverted cock structure, that is, the cock has its head pointing down. This inevitably reduces the sealing effect under the action of gravity. It has to be sealed by grease injection. It is used for storage and transportation of natural gas and oil, but cannot be used in other industries, because grease will contaminate the medium. Although the ball valve's sealing effect is slightly poor in theory, it can be made into a large caliber. With the improvement of processing accuracy and sealing material, the ball valve's sealing effect can already meet the actual application requirements, and the application range is wider. When used for adjustment, there is not much difference between the two, and appropriate holes can be made in the rotating body for adjustment. Therefore, the general plug valve is used in occasions with higher sealing requirements, but the diameter is generally smaller, and the ball valve can be applied to more and more extensive industrial occasions.