Metal sealed triple eccentric ball valve is a new product used in high temperature, high pressure, and harsh process medium requirements.

Advantages

Compared with ordinary soft-sealed ball valves

(1) Can be adapted to a wider temperature range. Soft-sealed ball valves are affected by the temperature resistance of non-metallic seals and cannot be used in situations where the temperature is too high. The metal seal can be used at 600 ℃ or even higher according to different materials.

(2) Can be used in higher pressure range. Limited by the pressure resistance of non-metallic materials and stability under high pressure, non-metallic sealed ball valves are used for CL600 or lower grades. When used at higher pressure levels, non-metallic seals are prone to instability and cause valve failure. The metal hard seal ball valve can be used in CL2500 class.

(3) A longer service life can be obtained. Compared with metal materials, non-metallic materials are prone to aging. After a period of use, the performance degradation of non-metallic materials will cause the valve sealing performance to also decrease. On the other hand, non-metallic materials are susceptible to damage. When the fluid contains solid particles, non-metallic seals are easily scratched, resulting in seal failure or reduced seal performance.

Compared with ordinary metal hard-sealed ball valves

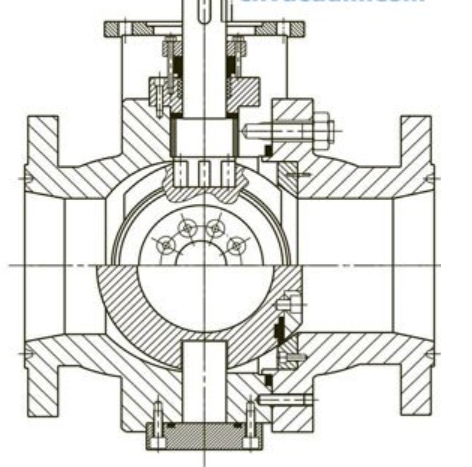

(1) Fixed ball design. Ordinary ball valves are sealed with floating balls, while triple eccentric ball valves are all designed with fixed balls, and the specific pressure of the seal is established by its own torque, which is reliable under any circumstances.

(2) Torque seal design. Traditional metal hard seal trunnion ball valves usually have a pre-compressed spring behind the valve seat. Under the action of the spring, the valve seat is in contact with the sealing surface of the ball to form a sealing specific pressure. If the spring stiffness is too small, the formed sealing specific pressure is also relatively small, and the sealing effect is poor; if the spring stiffness is high, the wear of the sealing surface will be increased, and the switching torque will be increased at the same time; on the other hand, the spring is affected by the temperature of the medium. Its stiffness tends to change over time, and therefore the sealing effectiveness also changes over time. The triple eccentric ball valve is sealed by torque, which can form a larger sealing specific pressure, and it will not wear a lot, and it will not be affected by temperature and alternating load.

(3) Bi-directional sealing performance of single valve seat. Under low temperature conditions, the traditional metal hard sealing ball adopts complex automatic pressure relief mechanism or adopts the method of opening holes in order to release the medium in the valve cavity. The former increases the complexity of the valve seat, and the latter makes the ball valve directional because of the opening. The triple eccentric ball valve adopts a single valve seat, so there is no problem of pressure release in the valve chamber. The triple eccentric structure makes the seat seal have a good sealing effect no matter in which direction, that is, it has a complete two-way sealing function.

Applications

1. High temperature working conditions (up to 600 ℃);

2. Low or ultra-low temperature working conditions (-196 ℃);

3. High pressure working conditions (up to CL2500);

4. Under hydrogen conditions;

5. Working conditions containing solid particles, etc.

With the development of petrochemical and coal chemical industries, the application of this type of valve will become more widespread.