Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

35~60 days Ex Works After Order ConfirmationMaterial:

WCB

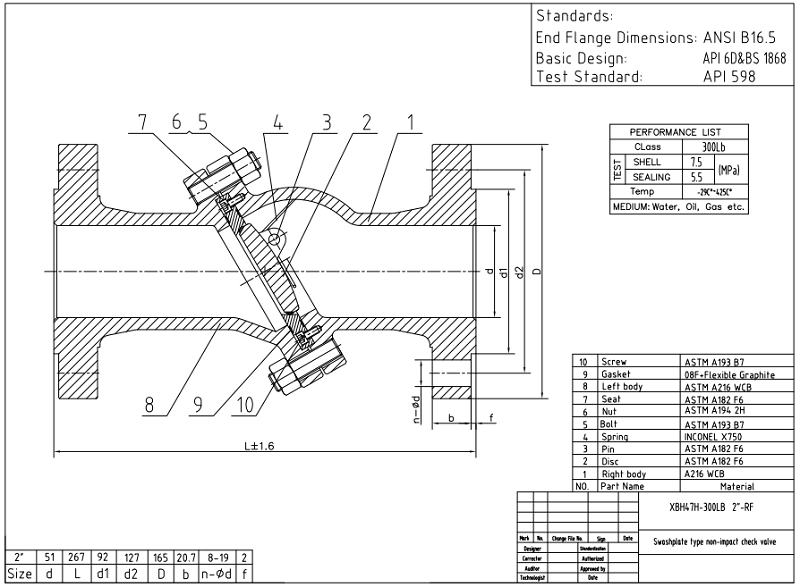

With the RF flange connection, the 2 inch tilting disc check valve is designed as per API 6D and made of carbon steel. It is suitable for the medium pressure up to 300 LB and temperature between minus 29 and 425 Celsius degree.

Quick Detail

|

Type |

Check Valve ( Non-return Valve) |

|

Nominal Diameter |

2’’ |

|

NominalPressure |

300LB |

|

Construction |

Tilting Type Disc |

|

Connection |

RF Flange |

|

Design & Manufacture |

API 6D,BS1868 |

|

End to End |

ASME B16.10 |

|

Flange End Dimension |

ASME B16.5 |

|

Test & Inspection |

API 598 |

|

Temperature Range |

-29℃~+425℃ |

|

Body Material |

Carbon Steel |

|

Media |

W.O.G. |

Technical Drawing

Our Main Product Range

With a complete product range, Dervos product lists cover gate, globe, check, ball, butterfly, check, plug valve and strainers. We can also provide marine valve, pressure reducing valve, control globe valve, wellhead valve and so on.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.