It is a Carbon Steel full bore flat gatevalve with parallel wedge, DN250 PN100, made from LCC, one kind of low-temp carbon steel, which makes this valve capable to handle extreme working conditions.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

LCCMethod of Operation:

pneumatic drive & HandwheelQuick Detail

|

Type |

Flat Gate Valve |

|

Nominal Diameter |

DN 250 |

|

Nominal Pressure |

PN 100 |

|

Construction Type |

Flat Type; with Drain Valve |

|

Connection Type |

EN1092-1 Type D |

|

Operation Type |

Pneumatic Actuator & Handwheel |

|

Body Material |

LCC |

|

Trim Material |

42CRMO4+TCC |

|

Design Code |

API6D |

|

End to End Code |

API6D |

|

Test & Inspection |

API 598 |

|

Temp.&Pressure |

ASME B16.34 |

|

Medium |

Water, Oil, Gas |

|

Origin |

China |

Features

-- Bonnet pressure self-sealed

-- design Fire proof design

-- Extended stem optional

-- Parallel Disc

-- Reliable internal and external sealing

-- Pressure self-relief design of valve pocket

-- Elastic gate design

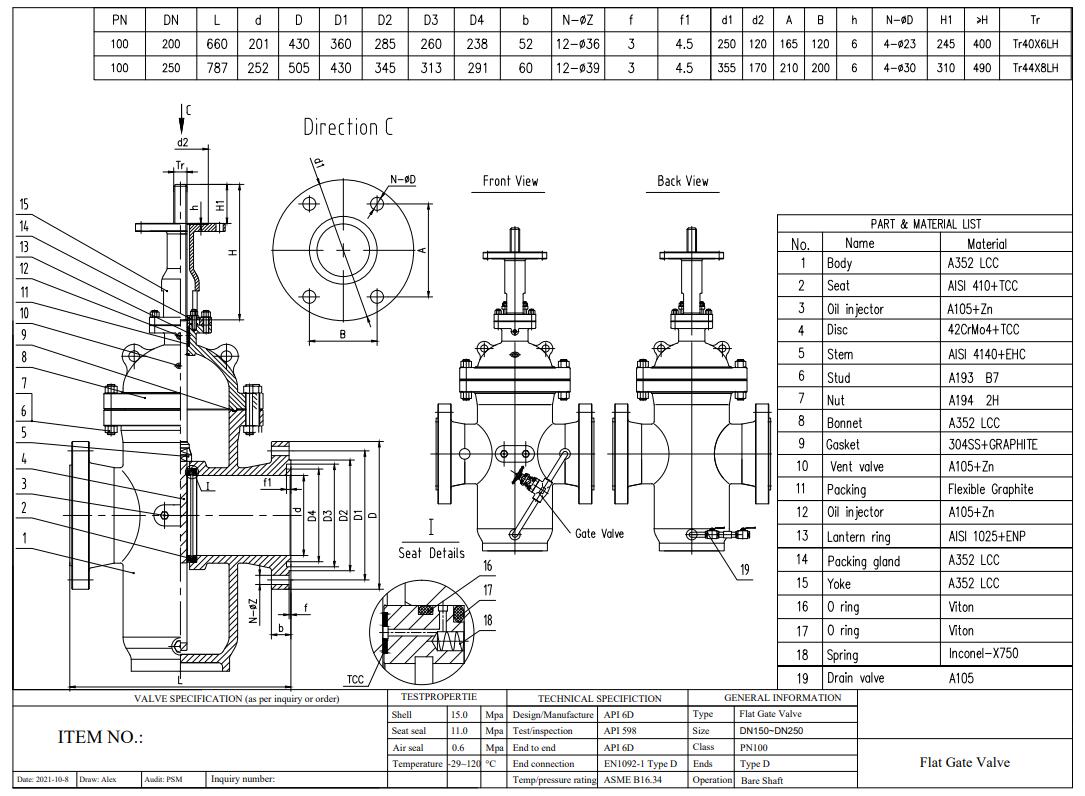

Technical Drawing

Dimension Check

Witnessing Tests

Product Display

Our Main Product Range

As an experienced supplier and vendor of industrial valves, Dervos supply cast steel valve, forged steel valve, cast iron valve, stainless steel valve, bronze valve, brass valve and alloy steel valve and so on, suitable for sea water, water, oil, and gas application.

Our Service

Dervos customer service is one of our biggest competitive advantages. In Dervos, we provide-

1. Quotation within 24 hours or no later than 3 days

This will let you meet the quotation submission deadline and enhance your working efficiency

2. Weekly status report of your order

In this way, you will have a clear picture of your order. You do not need to waste time on pushing us for status update

3. An 18-month warranty period

A warranty certificate will issued after shipment and you will not have any concern after buying valves.

4. Solutions to complaints within 3 days

Quick and responsible actions to complaints will protect your reputation and reduce the financial loss as much as possible.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.