Non-Lubricated, Sleeved Plug Valves incorporate state-of-the-artPPL seat design. With little required maintenance and trouble-free operation, the 3 inch 150 LB valve will ensure a high integrity bubble-tight seal.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

WCBMethod of Operation:

Pneumatic actuatorQuick Detail

|

Type |

Plug Valve |

|

Nominal Diameter |

3 Inch |

|

NominalPressure |

150 LB |

|

Construction |

Sleeved Type |

|

Connection |

RF |

|

Design & Manufacture |

API 599 |

|

End to End Dimension |

ASME B16.10 |

|

Test & Inspection |

API 598 |

|

Body Material |

A216 WCB |

|

Disc Material |

A315 CF8M |

|

Temp. Range |

≤180℃ |

|

Media |

W.O.G |

General Description

Sleeved plug valves are non-lubricated quarter-turn valves that achieve sealing through the use of a compressible sleeve as a sealing member.

Features

1. Its sealing is realized by the sealing face around the sleeve. It has unique 360 degree metal edge for protection and fixing of the sleeve.

2. No residue in the plug valve cavity.

3. Metal edge performs self-cleaning when the plug is rotated, applicable to the operation condition that is glutinous.

4. Its characteristic double-direction flow makes installation and use more convenient.

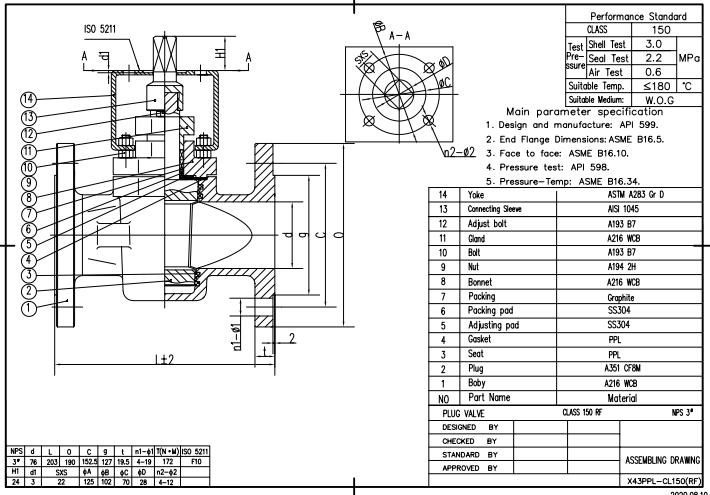

Technical Drawing

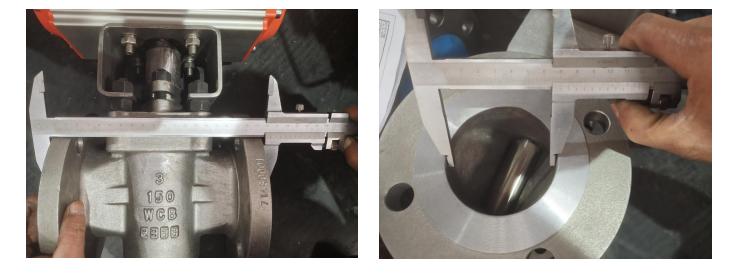

Dimension Check

Painting

Product Application

Dervos valves can be widely used in varieties of industries, such as petrochemical,pipeline,oil & gas,marine,water treatment,power station industries and etc.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.