Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

F11+STLMethod of Operation:

HandwheelQuick Detail

|

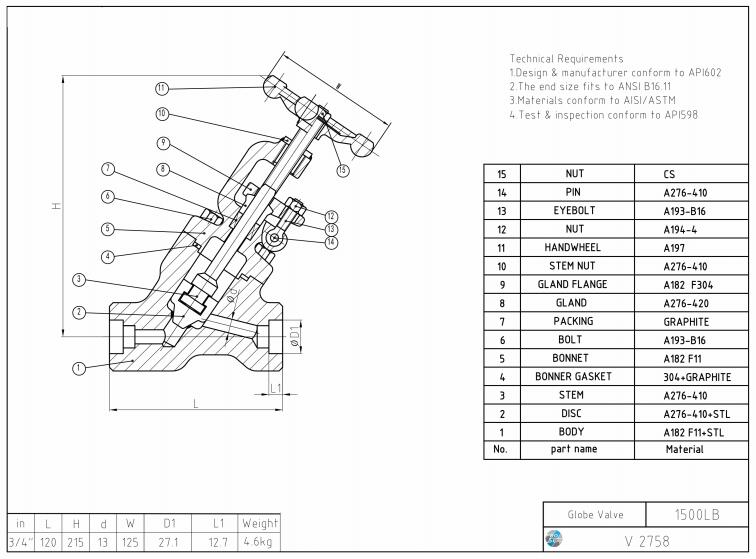

Type |

Globe Valve |

|

Designed Size |

3/4 Inch |

|

Designed Pressure |

1500LB |

|

Construction |

Y Type; Bolted Bonnet; |

|

Connection Type |

Socked Weld |

|

Operation |

Handwheel |

|

Design Code |

API602 |

|

Connection |

ANSI B16.11 |

|

Test & Inspection |

API598 |

|

Body Material |

A182 F11+STL |

|

Trim Material |

A276-410+STL |

|

Application |

Water, Oil, Gas |

Features

· Low pressure drop.

· Low torque stroking

· Quick and easy repair in line.

· Tight shutoff.

· Stem expansion/contraction thrust unit for high temperature application (optional).

· Other sizes available on request.

· Live-loading of packing optional.

Technical Drawing

Dimension Check

Witnessing Tests

Packing

Product Application

Dervos valves can be widely used in varieties of industries, such as petrochemical,pipeline,oil & gas,marine,water treatment,power station industries and etc.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.