Line blinds are utilized in pipeline systems when there is a need for either complete closure or unimpeded flow transition without a significant drop in pressure. The THD (Through-Hole Design) enables swift and seamless adjustments in position. The THD-slide variant boasts a multi-bolt configuration, making it easier to operate with reduced face-to-face dimensions. The inclusion of extra body bolts renders this style particularly well-suited for high-pressure applications.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationFeatures

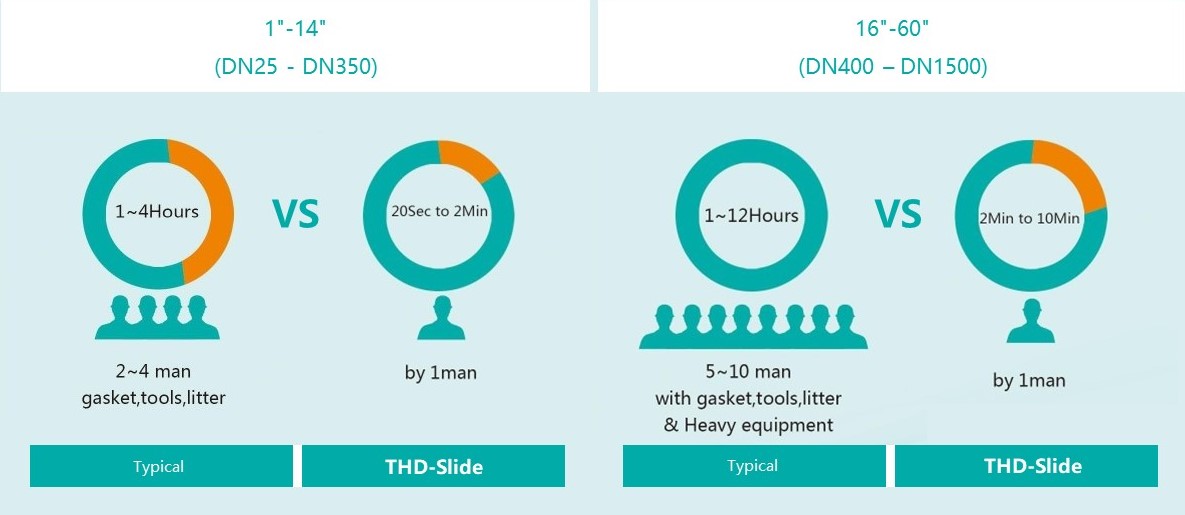

1. Swift Transition: Blinding can be performed safely in a matter of minutes, even by operators with minimal experience.

2. Economical Solution: Decreases maintenance hours, resulting in savings on labor costs.

3. Toolless Handling: The process is simplified with a hand-wheel operation, eliminating the need for tools to achieve full shut-off.

Standard Specifications

|

Size |

1'' - 60'' (DN 25 to DN 1500) |

|

Pressure Class |

Class 150 - 2500 (PN 2.5 to PN 400) |

|

Design & Manufacture code |

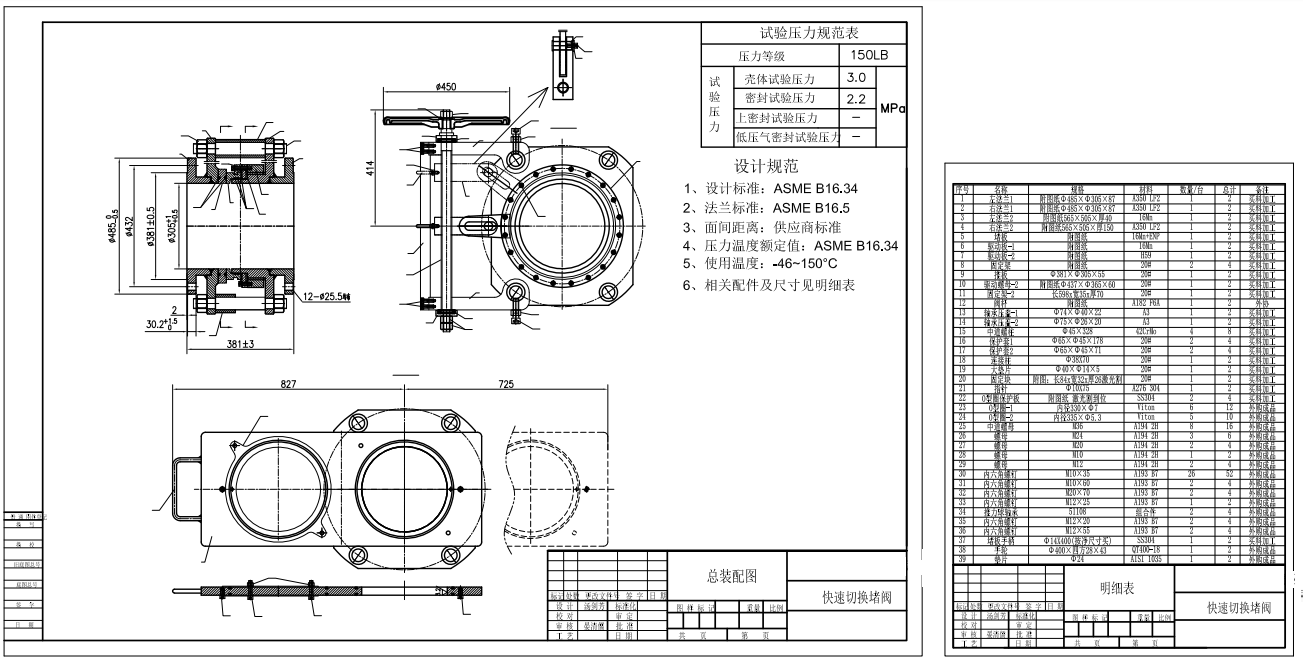

ASME B16.34 |

|

Flange Standard |

ASME B16.5 |

|

Material |

Carbon Steel, Stainless Steel, Hastelloy, and Titanium |

|

Actuation |

Manual, Pneumatic Hydraulic and Electric |

Technical Drawing

Adaptable Design

In addition to its conventional design, the THD-Slide is available in variations tailored for High-Temperature, Fire Safety, and Non-Drip applications. For installations constrained by limited space, a compact version can be provided as well.

Easy Seal Inspection

In this design, the seals are housed within the spectacle plate. This characteristic offers the advantage of convenient access for inspection and seal replacement. Assessing the condition of these seals can be performed external to the operational process, prior to any position changes, thereby ensuring the integrity of the seal's quality.

Cost Effectiveness

The THD-Slide features a straightforward and robust design engineered to deliver complete shutdown, extended operational lifespan, and cost-effective service with minimal maintenance requirements. The distinctive mechanism for opening and closing the THD-Slide enables a single individual to rapidly and safely blind pipelines without the need for any tools or equipment.

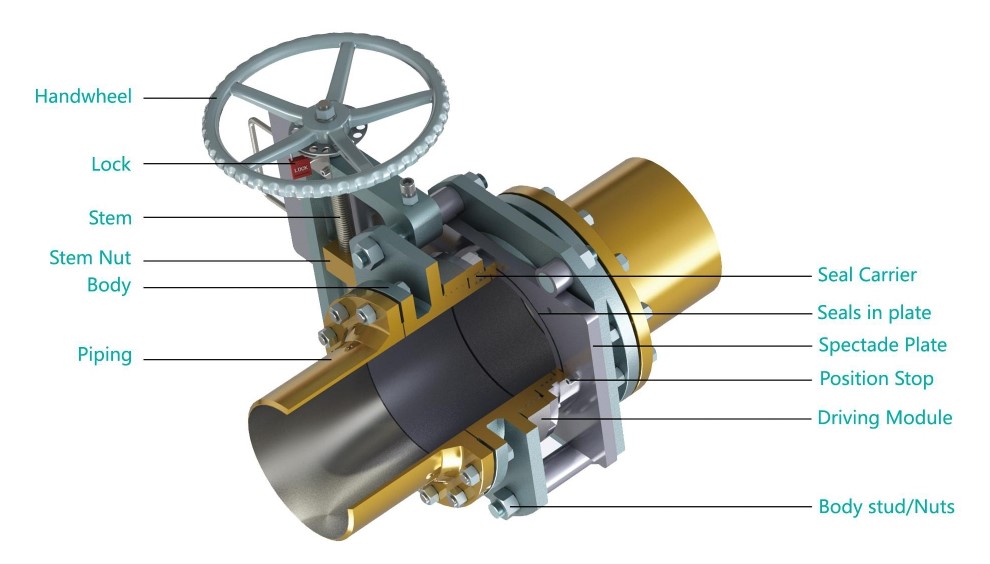

THD-Slide Cutout

Part Description

|

Part Description |

Material |

|

Handwheel |

QT400-18 |

|

Stem |

A182 F6A |

|

Stem Nut |

Alloy Copper |

|

Body |

A350 LF2 |

|

Seal Carrier |

A350 LF2 |

|

Seals in plate |

Viton |

|

Spectade Plate |

A350 LF2+ENP |

|

Position Stop |

A193 B7 |

|

Driving module |

A350 LF2 |

|

Body stud/Nuts |

A193 B7/A194 2H |

|

Other materials and seal rings are available upon request |

|

Options

●Hand Wheel Extensions

●Locking Device

●Limit Switches

●Drain/Vent ports

●Spectacle Plate Covers to Protect Seals

●Compact Design (integral tapped end flange)

●Rain/Dust Shield

●Torque Limiter

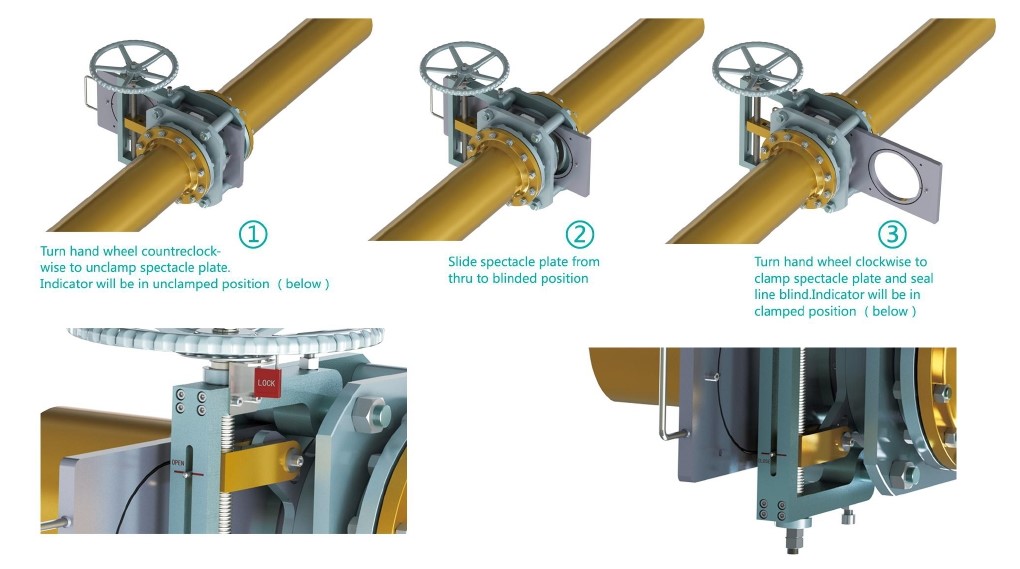

Operation of Standard

Mechanism Principle

In normal conditions, the blind valve's diversion hole is in contact with the pipeline, and the blind valve is in the open position. When maintenance is required, and the pipeline must be cut off, then loosen the stem of blind valve to move the flat end onto the pipeline, and make the blind valve turn to closed position from open position; tighten the stem and let the blind valve to perform sealing function and cut off the pipeline.

When the maintenance work is completed, loosen the stem and move the blind plate to the diversion hole and connected to the pipeline. The blind valve was turned to closed position from open one. Lock the stem, and seal it, the pipeline is now open, and the blind plate valve returns to the open position.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.